Miniflash for The Military

The Grabner Instruments® MARFLASH & NAVIFLASH was specifically designed for Marine or Shipboard applications and requires only 1.0 mL of sample which facilitates cool-down between tests, reduces fire hazard and minimizes sample disposal.

MINIFLASH is a uniquely designed flash point series of instruments for the automatic determination of the flash point of liquids and solid samples according to ASTM D6450 and the advanced

ASTM D7094 standard. This procedure describes the “Standard Test Method for Flash Point by Modified Continuously Closed Cup (MCCCFP)”, which offers the

highest repeatability and reproducibility and an excellent correlation to the D93 Pensky-Martens method:

"There is no statistically significant bias observed between ASTM D7094 and ASTM D93 Procedure A” as concluded during the last Round Robin. ASTM D7094 has been

approved by the ASTM committee for the Diesel Fuel and Kerosene specifications ASTM D975, D396, D2880 and D3699.

Furthermore, test results are equivalent to other well known standards such as Abel and TAG, and thanks to its unique design, MINIFLASH can be used for more difficult applications such as flash-point testing of contaminated samples like

diesel fuel in lube oil or

gasoline in diesel fuel and for biodiesel testing.

Its continuously closed cup design and small sample volume of only 1-2 mL offers

maximum safety, avoids offensive fumes in the testing area and reduces sample waste. The

fast thermoelectric cooling at the end of a test and the

fast and easy handling of the instrument, save expensive labor time.

Due to the true portability and rugged housing, the MINIFLASH is also the perfect solution for mobile labs and military applications.

The New Technology

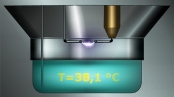

The MINIFLASH series of instruments is using the Grabner flash detection method of measuring the instantaneous pressure increase inside the continuously closed chamber due to a high energy electric arc. The fast thermoelectric cooling after each test prepares the instrument for the next test in a very short time. Heating the test chamber from the top avoids condensation of high volatile compounds, significantly improving the test results.

Peltier Protection Technology™

Peltier Protection Technology™

For a quick sample turnaround and extended instrument life time Grabner Instruments developed fast thermoelectric regulation of heating and cooling. This technology permits to extend the measuring temperature to well above 400°C and optimizes Peltier performance and life time.

Ignition Protection Technology™

Ignition Protection Technology™

Ignition Protection Technology™ is intrinsic to the MINIFLASH design. Only 1-2 mL of sample are required for testing the flash point - without an open flame! The continuously closed cup design, automatic explosion probing and a controlled air feed protect against fire and offensive fumes - for unmatched safety in flashpoint testing!

Wide Range of Applications

The flashpoint is determined over a wide temperature range, simulating all standard closed cup methods as well as GO/NOGO tests. Over the last years, the outstanding performance of MINIFLASH has proven effective for

transport regulations/classifications, product specifications and

used oil analysis (programmable fuel dilution curve to prevent costly engine troubles) in laboratories all over the world.

Flash Point of FAME (Biodiesel) and ASTM method D6751-03

Blending of Biodiesel (B100) with Diesel Fuels has become increasingly important in order to reduce the amount of carbon dioxide emission in the atmosphere. In the chemical reaction process to produce biodiesel, a short chain alcohol is used to dissolve the catalyst and to assist in the conversion of oil or fat into a fatty acid methyl ester (biodiesel). The excess alcohol is afterwards removed and measuring the flash point of each phase, with the MINIFLASH fully automatic flash point tester, provides a fast indication of the presence of any remaining flammable alcohol.